What keeps the world’s busiest food processing industries running smoothly day in and day out?

Behind every perfectly baked loaf of bread, finely chopped vegetable, or crispy fried snack lies a well-oiled system of advanced commercial kitchen equipment.

But what happens when even a single piece of equipment is outdated, inefficient, or missing from your industrial kitchen?

The consequences of such a failure could result in slowed down production, declined food quality, and floor-hitting revenues.

That’s why food processing companies, commercial kitchens, and caterers need machines that provide speed, precision, and consistency.

Moreover, these pieces of industrial kitchen equipment must justify the investment done by:

- Optimizing Workflow

- Increasing Productivity

- Maintaining Top-Notch Quality

So, what are the top 10 must-have pieces of equipment that every industrial kitchen absolutely needs?

And how can choosing the right machinery from trusted industrial kitchen equipment manufacturer enhance overall efficiency of the business?

Let’s explore the essential tools that no modern food processing kitchen can afford to miss.

Key Considerations When Choosing Commercial Kitchen Equipment

Selecting the right commercial kitchen equipment for an industrial kitchen can determine the success or failure of food production workflows.

In fact, for businesses in the food processing industry, choosing high-quality machinery is more than a preference—it’s a strategic necessity.

Here are the three critical factors to consider:

Durability

Industrial kitchens operate at high capacity, requiring machinery built to last.

Unlike regular kitchen appliances, industrial kitchen equipment is subjected to continuous heavy-duty use.

That’s why businesses choose equipment made from robust materials like stainless steel as they promise longevity, resists wear and tear, and meets hygiene requirements.

Efficiency

Strict timelines, and the perishable nature of raw materials, make efficiency a crucial element in the food processing industry.

Therefore, modern commercial kitchen machines are designed with automation, energy-saving features, and faster processing speeds in mind.

Reducing manual labour is not the goal here! On the contrary, these tools empower workers to be more productive, enhancing the overall value of operations.

Ultimately, efficiency-driven food processing machines aim to minimize energy and water consumption, and increase profitability.

Capacity

The scale of food production determines the capacity of your kitchen equipment.

For instance, in large-scale food processing plants, a high-capacity ginger and potato washing and peeling machine ensures that consistent quality is maintained during bulk production.

Choosing equipment that matches your production needs is essential to avoid bottlenecks.

Top 10 Must-Have Commercial Kitchen Equipment for Industrial Kitchens

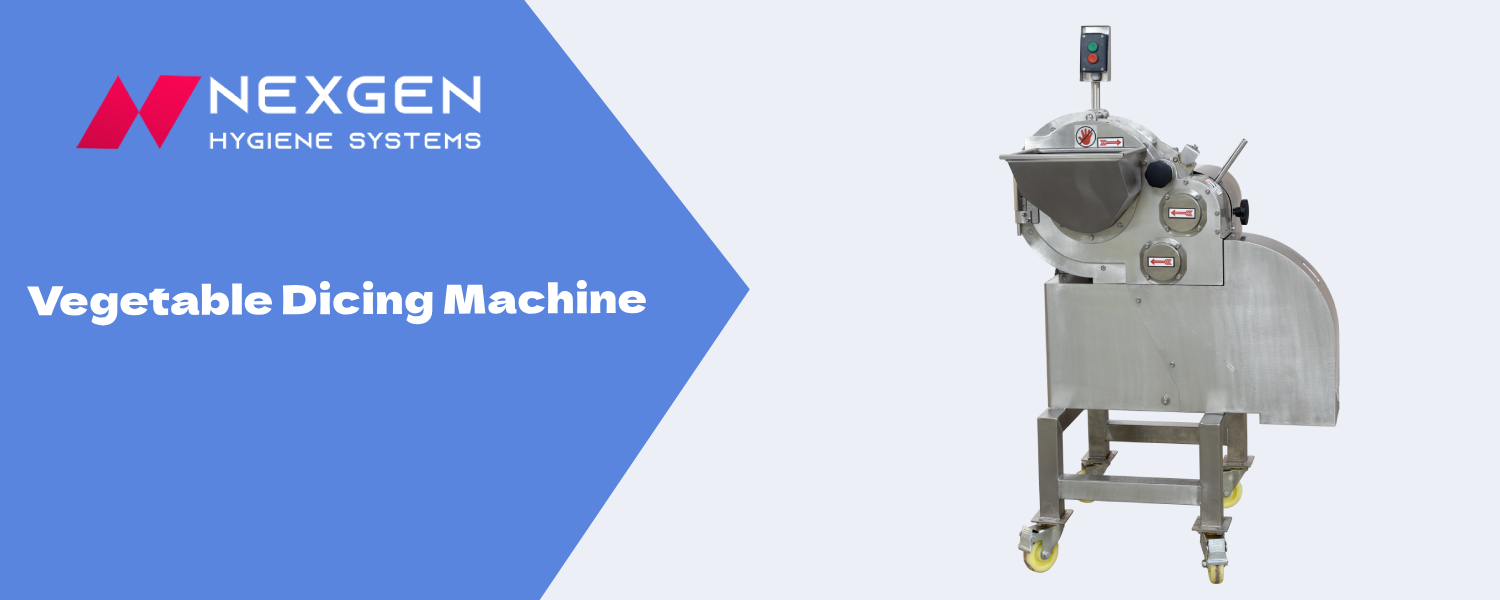

1. Vegetable Dicing Machine

The Vegetable Dicing Machine revolutionizes food prep in industrial kitchens, saving time and reducing waste.

Purpose: Dice vegetables into uniform shapes and sizes.

Key Features:

- Interchangeable blades for various cutting shapes.

- Stainless-steel construction for hygiene and durability.

- High-speed output with consistent performance.

Benefits: Speeds up food preparation, ensures consistency, and reduces manual labor.

Use Case: Ideal for catering businesses, frozen food industries, and commercial kitchens.

2. Garlic Peeling Machine

The Garlic Peeling Machine automates the labor-intensive task of peeling garlic without damaging the cloves.

Purpose: Peel garlic efficiently in bulk quantities.

Key Features:

- Gentle air-blowing system to preserve clove integrity.

- Easy-to-clean design for enhanced hygiene.

- High peeling efficiency with minimal wastage.

Benefits: Saves time, boosts productivity, and reduces manual effort.

Use Case: Essential for food processing units, seasoning manufacturers, and bulk food kitchens.

3. Tilting Vegetable Washer

The Tilting Vegetable Washer ensures thorough cleaning of vegetables while simplifying unloading.

Purpose: Clean large volumes of vegetables efficiently.

Key Features:

- Tilting design for easy loading and unloading.

- Water circulation system for deep cleaning.

- Durable, food-grade material construction.

Benefits: Removes dirt, contaminants, and pesticides while maintaining freshness.

Use Case: Suitable for commercial kitchens, food processing plants, and large-scale catering operations.

4. Onion Peeling Machine

The Onion Peeling Machine eliminates the hassle of manually peeling onions in bulk.

Purpose: Peel onions quickly without damaging the outer layers.

Key Features:

- High-capacity peeling mechanism.

- Minimal peeling loss for reduced wastage.

- Hygienic stainless-steel build.

Benefits: Saves time, minimizes irritation, and boosts kitchen productivity.

Use Case: Used in large food processing units, catering services, and packaged food industries.

5. Leafy Vegetable Cutting Machine

The Leafy Vegetable Cutting Machine simplifies the processing of delicate leafy greens.

Purpose: Cut leafy vegetables like spinach, cabbage, and lettuce uniformly.

Key Features:

- Adjustable cutting settings for different thicknesses.

- Gentle processing to preserve texture.

- High-output capacity for bulk kitchens.

Benefits: Maintains freshness, ensures precision, and reduces manual labor.

Use Case: Ideal for salad processing units, catering businesses, and vegetable packaging plants.

6. Multipurpose Vegetable Washer

The Multipurpose Vegetable Washer ensures clean, contaminant-free vegetables in large batches.

Purpose: Wash multiple vegetable types simultaneously.

Key Features:

- Advanced water circulation for deep cleaning.

- High-capacity design for bulk washing.

- Compact footprint for space-saving operations.

Benefits: Enhances hygiene, removes contaminants, and saves labor.

Use Case: A must-have for food processors, central kitchens, and industrial catering units.

7. Pouch Drying Machine

The Pouch Drying Machine efficiently dries packaged food items after washing or filling.

Purpose: Remove moisture from pouches, ensuring they are clean and dry.

Key Features:

High-speed air-drying technology.

Adjustable settings for different pouch sizes.

Low energy consumption for cost efficiency.

Benefits: Reduces packaging delays and ensures product readiness for storage or distribution.

Use Case: Ideal for food packaging units, sauce manufacturers, and beverage industries.

8. Crate Washing Machine

The Crate Washing Machine automates the cleaning of storage and transportation crates for food safety.

Purpose: Clean crates efficiently to maintain hygiene standards.

Key Features:

- High-pressure washing system for thorough cleaning.

- Stainless-steel construction for durability.

- Fast cleaning cycle for increased productivity.

Benefits: Ensures food safety, reduces contamination risk, and saves manual labor.

Use Case: Widely used in food processing industries, cold storage units, and transport facilities.

9. Centrifugal Dryer

The Centrifugal Dryer accelerates drying of washed vegetables and food items by removing excess water.

Purpose: Spin-off moisture quickly after washing.

Key Features:

- High-speed centrifugal spinning for efficient drying.

- Robust, stainless-steel design for durability.

- Compact design for ease of operation.

Benefits: Reduces drying time, prevents spoilage, and improves food preparation efficiency.

Use Case: Perfect for vegetable processing plants, frozen food manufacturers, and catering kitchens.

10. Chopping Machine

The Chopping Machine simplifies the preparation of bulk food items by delivering precise and uniform chopping results.

Purpose: Cut vegetables and fruits into smaller, uniform pieces efficiently.

Key Features:

- Adjustable chopping settings for varied sizes.

- Heavy-duty stainless-steel construction for durability and hygiene.

- High-speed operation for bulk food preparation.

Benefits: Enhances kitchen productivity, reduces manual labor, and ensures consistency in chopping.

Use Case: Perfect for food processing plants, catering kitchens, and frozen food industries.

Benefits of Investing in the Right Industrial Kitchen Equipment

Improved Efficiency

High-quality industrial food processing equipment automates tasks, reduces production time, and increases output.

As a result, the food business is able to meet production deadlines without compromising quality.

Cost Savings

Industrial-grade machines may seem like a large investment. But, they ultimately result in long-term savings.

Automation in the food processing industry lowers costs in several ways:

- Heightened production without the need to significantly expand the workforce, as automation allows each worker to give more productivity.

- Automated food processing machineries are “energy-smart” as they efficiently utilize electricity. Consequently, energy bills are lower in comparison to the volume of the product outputs.

- Durable equipment depreciates at a much lower rate. This, in turn, minimizes the repair expenses.

Enhanced Food Quality

Whether it’s the chopped veggies, or peeled onions, product consistency is crucial for smooth sailing of food processing.

High-tech food processing machinery guarantees uniformity of the output. This helps the industry to meet the quality standards and consumer expectations.

Compliance with Food Safety Standards

Modern industrial kitchen equipment helps food-related businesses to meet domestic and global hygiene standards.

To comply with all safety and hygiene standards, these machines are designed with:

- Easy-to-clean surfaces

- Automated processes

- Proper temperature controls

- Features that mitigate the risk of contamination

How to Choose Reliable Industrial Kitchen Equipment Manufacturers?

Finding the right industrial kitchen equipment manufacturers is essential for acquiring machinery that delivers both quality and value.

Here’s what to look for while choosing the right food processing machine makers for your business:

- Industry Reputation: Choose manufacturers that have a proven track record in the food industry. Have a look at what their clients are saying – testimonials and case studies are strong indicators of reliability.

- After-Sales Support: Make sure the manufacturer offers comprehensive support, including installation, training, and ongoing assistance. Good after-sales service can save you a lot of headaches and downtime.

- Customization Options: Every food processing operation is different. Look for a manufacturer that can adapt to your specific needs and offer customized solutions that deliver the best value.

Example: Manufacturers like Nexgen Industrial offer a wide range of food processing machines. They also provide end-to-end support, from consultation and installation to reliable (post-sales) customer service.

Key Maintenance Tips for Longevity of Kitchen Equipment

To get the most out of your industrial kitchen investment, regular maintenance is crucial.

Here are some recommendations to boost the lifespan of your equipment:

Clean Equipment Regularly

Remove food residues and grease to prevent clogging and contamination.

Inspect Parts

Regularly check for wear and tear to avoid unexpected breakdowns.

Lubricate Moving Parts

Proper lubrication ensures smooth operation and prevents damage.

Schedule Professional Servicing

Annual professional maintenance checks extend the lifespan of your equipment.

By following these maintenance practices, you can reduce repair costs and maximize the efficiency of your kitchen equipment.

Conclusion

Investing in the right industrial kitchen equipment results in better efficiency, improved hygiene standards, and accelerated production speeds.

While ‘industry’ often refers to food processing units, these machines have a much wider application.

The large-scale capabilities of commercial food processing machinery make them ideal for catering businesses, welfare societies, and religious institutions that need to prepare food for large numbers of people.

Need a reliable vegetable dicer? A powerful chopping machine? Or maybe an efficient crate washer? Nexgen has your back!

We specialize in crafting top-performing food processing equipment, designed specifically for your factory.

Contact us today for a personalized consultation.

FAQs

What are the key benefits of using industrial kitchen equipment in food processing?

Industrial kitchen equipment ensures precision, consistency, and efficiency in food processing.

For example, high-capacity machines like vegetable dicers, chopping machines, and crate washers automate labor-intensive tasks, reducing manual effort and speeding up production.

These machines help to maintain food quality by delivering uniform results and complying with hygiene standards, making them essential for large-scale kitchens.

How do I choose the right industrial kitchen equipment for my factory?

When selecting industrial kitchen equipment, consider factors such as capacity, durability, efficiency, and compliance with food safety regulations.

For instance, equipment made from stainless steel offers hygiene and longevity. On the other hand, machines with adjustable settings and automation make the operations smoother and simpler.

Alternatively, consult with reputable manufacturers, like Nexgen. They can help you with customized solutions tailored to your production needs and business goals.

What is the difference between commercial kitchen equipment and regular kitchen appliances?

Regular kitchen appliances are meant for micro-scale food processing. However, commercial kitchen equipment is designed for heavy-duty, continuous operations in industrial settings.

In contrast to regular kitchen appliances, food processing equipment offers greater capacity, speed, and durability.

For example, a chopping machine processes bulk vegetables quickly, whereas a household food chopper handles smaller volumes at slower speeds.

Industrial kitchen equipment also includes conveyors for material handling, which is not required in small-scale tiffin centres or house kitchens.

How does investing in the right industrial equipment improve profitability?

Investing in high-quality industrial equipment can make a big difference in your operational efficiency.

For example, machines like tray dryers automate drying processes. Or, a custard apple pulper can empower an ice-cream or juice packaging business with smooth and uniform pulp extraction.

Consequently, you achieve a faster workflow resulting in:

- Increased output

- Minimal wastage

- Consistent product qualityAll these factors ultimately boost your revenue and customer satisfaction

Why is maintenance critical for industrial kitchen equipment?

Regular maintenance prolongs the lifespan of industrial kitchen equipment and ensures uninterrupted performance.

Tasks such as cleaning equipment surfaces, inspecting moving parts, and scheduling professional servicing prevent breakdowns and contamination.

In conclusion, proper maintenance reduces downtime, repair costs, and ensures compliance with food safety standards.