Hygiene stations are specialized equipment and setups designed to maintain cleanliness and sanitation within food processing plants and other industrial facilities. They play a crucial role in ensuring a safe and hygienic production environment, helping to prevent contamination and uphold food safety standards.

Hygiene Stations

For a Secured Production Journey

Designed to uphold the highest standards of cleanliness, these stations integrate seamlessly into your workflow, ensuring safe, sanitary, and efficient operations.

Features of Hygiene Stations

Hand Washing and Sanitizing

Stations equipped with sinks, soap dispensers, and sanitizers to promote proper hand hygiene for workers.

Boot and Shoe Cleaning

Equipment such as boot scrubbers and shoe sanitizers to remove contaminants from footwear.

Access Control

Often located at entry and exit points, these stations can help control access to production areas, ensuring only properly sanitized personnel and equipment enter.

Monitoring and Compliance

Some stations may include technology to track hygiene compliance and ensure that no cycle is skipped before entering the production area.

Customization

HMI is provided with the machine. Duration of each cycle can be adjusted according your needs with the help of the HMI.

SOLUTION HIGHLIGHT

Explore Our Products

IMPACT

Importance of Hygiene Stations

Prevention of Contamination

Hygiene stations help prevent the spread of contaminants, such as bacteria and pathogens, that can compromise food safety and quality.

Compliance with Regulations

By facilitating proper hygiene practices, these stations help businesses meet industry regulations and standards, such as those set by the FDA and other food safety organizations.

Enhanced Worker Safety

Proper hygiene practices protect workers from exposure to harmful substances and maintain a healthy work environment.

Protection of Consumers

Ensuring high hygiene standards helps prevent contaminated products from reaching consumers, protecting their health and your business’s reputation.

Increased Efficiency

Streamlined hygiene procedures contribute to a smoother production process by minimizing the risk of contamination-related downtime.

Cost Savings

By preventing contamination and potential recalls, hygiene stations can lead to significant cost savings for businesses.

Improved Employee Morale

Providing workers with the tools and equipment for proper hygiene can boost morale and demonstrate a company’s commitment to their well-being.

APPLICATIONS

Industry Applications

Hygiene stations have a wide range of industry applications where cleanliness and safety are paramount. Here are some of the key industries that benefit from hygiene stations:

Food Processing

Beverage Production

Pharmaceuticals

Healthcare

Cosmetics and Personal Care

Meat and Poultry Processing

Dairy Processing

Chemical and Petrochemical

Why Choose Nexgen Hygiene Systems

Nexgen Hygiene Systems stands out as a trusted partner in providing innovative and reliable hygiene solutions for your business. We offer a comprehensive range of cutting-edge products and services designed to streamline operations, enhance cleanliness, and improve efficiency. With our commitment to quality, customer satisfaction, and industry expertise, we are the go-to choice for businesses seeking to elevate their production journey.

Expertise and Experience

With over 20 years of industry experience, we understand your specific needs and deliver tailored solutions to meet them.

Quality and Reliability

Our products are engineered for durability and performance, ensuring consistent results and long-term value.

Customer-Centric Approach

We prioritize your success, offering exceptional support and personalized service to help you achieve your operational goals.

OUR CLIENTS

Delivering excellence in every partnership

FAQs

Frequently Asked Questions

Where should hygiene stations be placed?

Hygiene stations are typically located at key points in a facility, such as entry and exit points of production areas, to ensure workers follow proper hygiene protocols before and after entering.

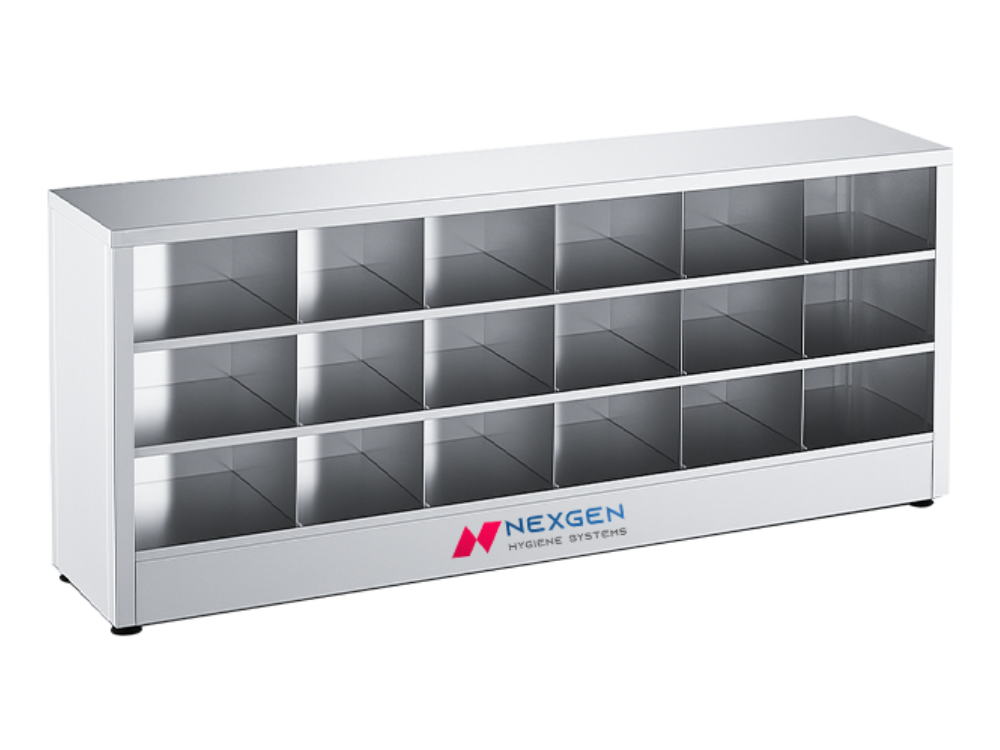

What features should I look for in a hygiene station?

Look for stations that offer hand washing and sanitizing facilities, boot and shoe cleaning equipment, protective gear storage, and easy-to-clean surfaces. Automated features can also help improve efficiency.

How can hygiene stations improve my production processes?

Hygiene stations streamline operations by reducing contamination risks, which can lead to fewer production interruptions and better product quality.

Are hygiene stations easy to maintain?

Yes, our hygiene stations are designed for easy cleaning and maintenance. Look for models with smooth surfaces and simple designs that can be quickly sanitized.

How can I ensure my hygiene station is effective?

Regular maintenance, staff training, and consistent monitoring of hygiene practices can help ensure your hygiene station remains effective in maintaining a clean and safe environment.

Can hygiene stations be customized?

Yes, many hygiene stations can be tailored to fit your specific facility needs, including size, configuration, and features.

Do hygiene stations require special installation?

While some hygiene stations may require specific installation, many are designed for easy setup and integration into your existing facility layout.

How do I choose the right hygiene station for my facility?

Consider your facility’s specific needs, such as the size of your workforce, production volume, and available space. Look for stations with the features that best support your operations and hygiene protocols.