The demand for ready-to-eat (RTE) foods is rising, and manufacturers are under increasing pressure to meet consumer expectations for speed, quality, and affordability. With growing competition and a need for scalable production, automation is playing a crucial role in improving manufacturing efficiency. In particular, vegetable processing machines are revolutionizing the way vegetables are prepared in the food industry, making processes faster, more hygienic, and more cost-effective.

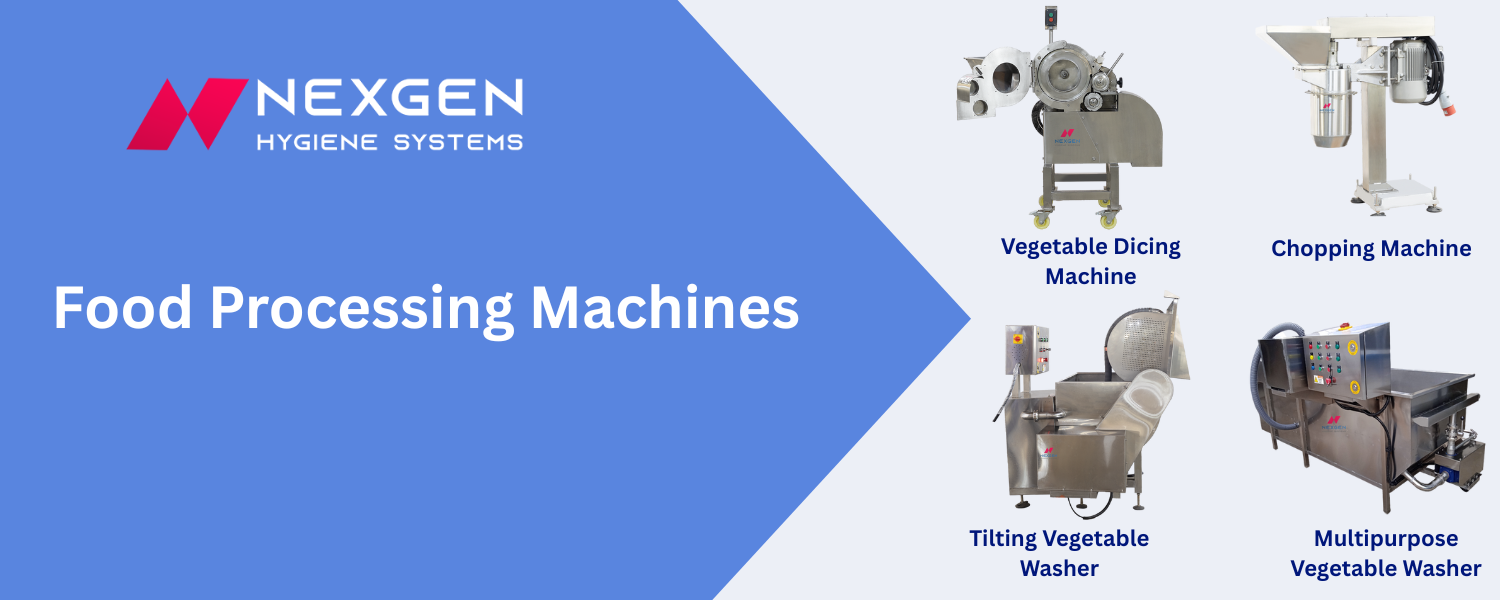

For RTE food manufacturers, automation is no longer a luxury but a necessity. From vegetable cutting machines to commercial vegetable washers, these automated systems streamline production while maintaining the high standards of hygiene and consistency required in food processing.

Streamlining Production with Automation in Vegetable Processing

Automation has significantly impacted vegetable processing, with machines designed to handle tasks like washing, cutting, peeling, and sorting more efficiently than manual labor ever could.

Reduced Manual Handling: One of the primary benefits of automation is the reduction in manual labor. Automated food processing equipment performs repetitive tasks faster and with greater accuracy, leading to quicker turnarounds on production lines.

Production Efficiency: Automated machines handle high volumes of vegetables in less time. For instance, a multipurpose vegetable washer can wash large quantities at once, ensuring uniformity and speed. With the help of automated vegetable processing machines, manufacturers can scale their operations without compromising quality.

Reducing Labor Costs with Automated Vegetable Processing Machines

The cost-saving potential of automated systems is one of the most compelling reasons for manufacturers to invest in vegetable processing automation. With reduced dependency on manual labor, companies can allocate their workforce to higher-value tasks, such as quality control and R&D, instead of repetitive actions like sorting or washing.

Lower Labor Dependency: Automation minimizes the need for operators to perform manual work such as cutting, peeling, or washing. Systems like vegetable cutting machines and commercial vegetable washers can work continuously, reducing the need for additional manpower.

Cost Savings: While the initial investment in food processing machines may be higher, the long-term savings in labor costs, reduced errors, and optimized staffing make it a worthwhile investment. Not only does it reduce human error, but it also ensures higher consistency in product output.

Employee Focus: Automation frees up workers to focus on more critical aspects of production, such as ensuring the product meets quality standards or managing inventory.

Increasing Production Speed with Automation

Speed is essential in the food industry, especially when it comes to meeting high demand and ensuring fast delivery. Automated vegetable processing machines like commercial vegetable washers can improve throughput and reduce bottlenecks in the production line.

Faster Throughput: Automated systems can handle larger quantities of vegetables faster than manual labor, speeding up production cycles and helping manufacturers meet demand spikes more efficiently.

Consistency at Scale: Maintaining the same level of quality across large batches is often difficult with manual processes. Automation ensures that every batch of vegetables is processed in the same way, providing the consistency required in RTE food production.

Batch Processing: Automation also improves batch processing. Machines like vegetable cutting machines can slice vegetables with precision, ensuring that each batch meets the required specifications for texture, size, and quality.

Ensuring Consistent Quality Across All Production Batches

One of the most significant challenges for RTE food manufacturers is maintaining consistent product quality across all batches. Automated vegetable processing machines help ensure that each vegetable is processed to the same high standard.

Uniformity in Processing: Machines like food processing equipment are designed to process vegetables consistently. Automated vegetable cutting machines ensure that every piece is cut to the same size, while commercial vegetable washers clean each item uniformly.

Precision and Control: Automated systems allow manufacturers to set precise parameters for temperature, speed, and wash time. This level of control minimizes variability and ensures consistent texture and quality across all production batches.

Reducing Human Error: Automation reduces the chances of human error, ensuring that every batch of vegetables meets the desired standards for hygiene and product quality.

Enhancing Food Safety and Hygiene Standards

Food safety is one of the most critical aspects of RTE food production. Automation in vegetable processing helps manufacturers meet the strict hygiene standards required in the industry.

Hygiene Compliance: Automated systems like commercial vegetable washing machines and food processing machines minimize human contact with vegetables, reducing the risk of contamination. Automation ensures that washing and sanitizing processes are completed consistently and in compliance with food safety regulations.

Integrated Sanitization: Many automated vegetable processing machines feature built-in sanitization capabilities, ensuring that each vegetable is cleaned thoroughly and consistently.

Traceability: Automated systems provide better traceability of processed vegetables, allowing manufacturers to track the entire production process and comply with audits and safety standards like FSSAI, GMP, and ISO.

The Future of Automated Vegetable Processing in the RTE Industry

As automation continues to evolve, new technologies and innovations are improving how vegetables are processed in RTE food manufacturing.

Innovation in Automation: Advancements such as AI-driven quality control, robotic arms for sorting, and IoT-powered performance monitoring are expected to make vegetable processing machines even more efficient and intelligent.

Impact on RTE Production: The future of automation will provide RTE food manufacturers with even more flexibility, allowing for rapid adjustments to production lines, quicker adaptation to consumer trends, and improved sustainability.

Adapting to Consumer Preferences: As consumer demands for variety and customization in RTE foods continue to grow, automation will allow manufacturers to process vegetables in more innovative ways, adapting quickly to the needs of the market.

Want to stay ahead of industry trends?

Contact UsConclusion

Automation in vegetable processing is changing the way RTE food manufacturers operate, offering them the opportunity to streamline production, reduce labor costs, and improve consistency. With the help of vegetable processing machines, commercial vegetable washers, and food processing equipment, manufacturers can ensure better product quality, faster processing times, and lower operational costs.

For manufacturers looking to stay ahead in the competitive RTE food market, investing in automation is key. Contact Nexgen Machines today to discover how our vegetable processing solutions can optimize your production line for efficiency, consistency, and hygiene.

FAQs

What are the key benefits of automating vegetable processing for RTE food manufacturers?

Automation helps improve production efficiency, reduce labor costs, and ensure consistent quality. It minimizes human error and enhances hygiene standards across the entire process.

How does automation help maintain consistent quality in vegetable processing?

Automated systems ensure precise control over parameters like cutting size, temperature, and wash time, which results in uniform processing and consistent product quality.

Are automated vegetable processing machines cost-effective for RTE food manufacturers?

Yes, while the initial investment may be higher, the long-term cost savings from reduced labor, fewer errors, and faster throughput make automation a smart investment for RTE manufacturers.

What are the food safety advantages of using automated vegetable processing machines?

Automation helps maintain hygiene by reducing manual handling and ensuring consistent sanitization. It also improves traceability, making it easier to comply with food safety regulations.