When it comes to food and beverage processing industry, efficiency and hygiene are key. In an industry where every second counts, the tools you use can make or break your operation. The air knife drying system is one such tool that’s been making waves in the Beverages food processing sector. This technology has transformed how food products are dried, cleaned, and cooled, offering a streamlined solution to many of the challenges faced by food processors today.

But what exactly is air knife technology, and why has it become so crucial in modern food processing? In this article, we’ll break down how air knives work, explore the different types used in the industry, and examine the wide range of food products that benefit from this technology. We’ll also take a closer look at the key advantages air knives offer for enhancing productivity, reducing waste, and ensuring food safety.

What is Air Knife Technology?

An air knife is a specialized system that generates a high-velocity, uniform sheet of air. This powerful stream is used to blow off water, debris, or other unwanted materials from a product’s surface. The non-contact nature of air knife systems makes them ideal for beverage and food processing, where maintaining hygiene and product integrity is critical.

An air knife drying system creates a controlled curtain of air, allowing it to dry, clean, or cool food products without compromising their quality. This process is highly efficient, ensuring that moisture or contaminants are removed uniformly, which is essential for preventing spoilage or maintaining food safety.

Types of Air Knives Used in Beverage and Food Processing

There are several types of air knives, each designed for specific applications:

Standard Aluminuim Air Knives

These are commonly used for drying and cooling. They offer uniform air distribution and are versatile in various food processing tasks.

Flat Nozzle Air Knives

Used for directing air flow to dry specific products more efficiently. Eg: Drying of gusseted pouches.

Stainless Steel Air Knives

Designed for high risk areas where risk of corrosion is high. Characteristics are similar to aluminuim air knives.

Ionizing Air Knives

These are specially designed to neutralize static electricity, making them useful in processes where static buildup is a concern.

The Role of Air Knife Technology in Modern Beverages and Food Processing

Air knife technology has become indispensable in the industry for several key reasons, including its ability to enhance drying, cleaning, and cooling processes. By delivering precise airflow, air knife systems ensure high-quality results, making them an integral part of modern food processing.

Efficient Drying of Food Products

Air knives excel at drying food products quickly and effectively. Whether it’s removing moisture from packaging surfaces before labeling or ensuring that containers are completely dry before sealing, air knives offer a non-contact solution that maintains product quality. The air knife system directs a powerful sheet of air across the surface of the food item, removing excess moisture without affecting texture, taste, or appearance.

In many cases, traditional drying methods use heat, which can degrade the quality of food products. Air knife systems eliminate this concern by using cool, high-velocity air to dry the products. This ensures packaging materials remain free from moisture, ready for the next stage of processing, while maintaining the overall quality and appearance of the products.

Enhanced Cleaning and Contaminant Removal

The food processing industry places a high priority on cleanliness and hygiene. Air knives play a critical role in removing debris, dust, and other contaminants from food products. The non-contact nature of air knife cleaning makes it an excellent solution for environments that require strict hygiene controls.

A powerful stream of air can blow off even the smallest particles, reducing the risk of contamination and ensuring a higher level of food safety. For instance, air knives are often used to clean bottles, cans, and other packaging before they are filled or sealed. This helps ensure that the packaging is free from dust or moisture that could compromise product safety.

Cooling and Drying of Retort Pouches Without Contamination

In food processing, certain products such Ready to Eat (RTE) foods need to be cooled after the retort process, before they can be packaged or moved to the next stage of production. Traditional cooling methods, such as water immersion or direct-contact cooling, can introduce contaminants or additional moisture, which poses a risk to product safety.

Air knife systems offer a hygienic, non-contact method for cooling products. By directing a controlled flow of air, food items can be cooled down rapidly without the risk of contamination.

Why Air Knife Technology is Crucial in the Food Industry

- Efficiently dries products before packaging, maintaining product quality.

- Prepares packaging materials for accurate labeling by removing moisture or debris.

- Removes surface moisture from bottles, cans etc before labelling and coding applications.

- Removes surface moisture from products before further processing or cooking.

- Effectively defrosts or removes ice from frozen goods, ensuring proper handling.

- Helps maintain a fully sanitized and hygienic production environment.

- Utilizes FDA-compliant stainless steel air knives suitable for corrosive and wash-down environments.

- Provides oil-free and moisture-free air, meeting stringent food safety and hygiene standards.

Food Products Covered by Air Knife Technology

Fresh Produce

Air knives are widely used to dry fruits and vegetables after washing. Whether it’s leafy greens, tomatoes, or apples, the high-velocity air stream ensures that moisture is removed quickly and evenly, preserving freshness and extending shelf life.

Bakery Products

Baked goods like bread, pastries, and cakes often require precise drying or cooling before packaging. Air knives effectively remove surface moisture and cool baked items, ensuring they retain their texture, quality, and appearance.

Frozen Foods

Air knives are instrumental in the defrosting or removal of ice from frozen products like vegetables, meats, and seafood. By using non-contact air streams, they help maintain the integrity of frozen items without adding additional moisture.

Confectionery

Chocolate, candy, and other coated confectionery products benefit from air knife technology to regulate the application of coatings. Air knives ensure that coatings like chocolate or sugar are applied evenly, preventing waste and maintaining product quality.

Meat and Poultry

Air knives help in both cleaning and cooling processes for meat and poultry products. They remove moisture and debris before packaging, ensuring that the products remain fresh and free from contaminants.

Dairy Products

In dairy processing, air knives are used to remove moisture from cheese and yogurt packaging, as well as to regulate coatings applied to certain cheese products, ensuring consistency and uniformity.

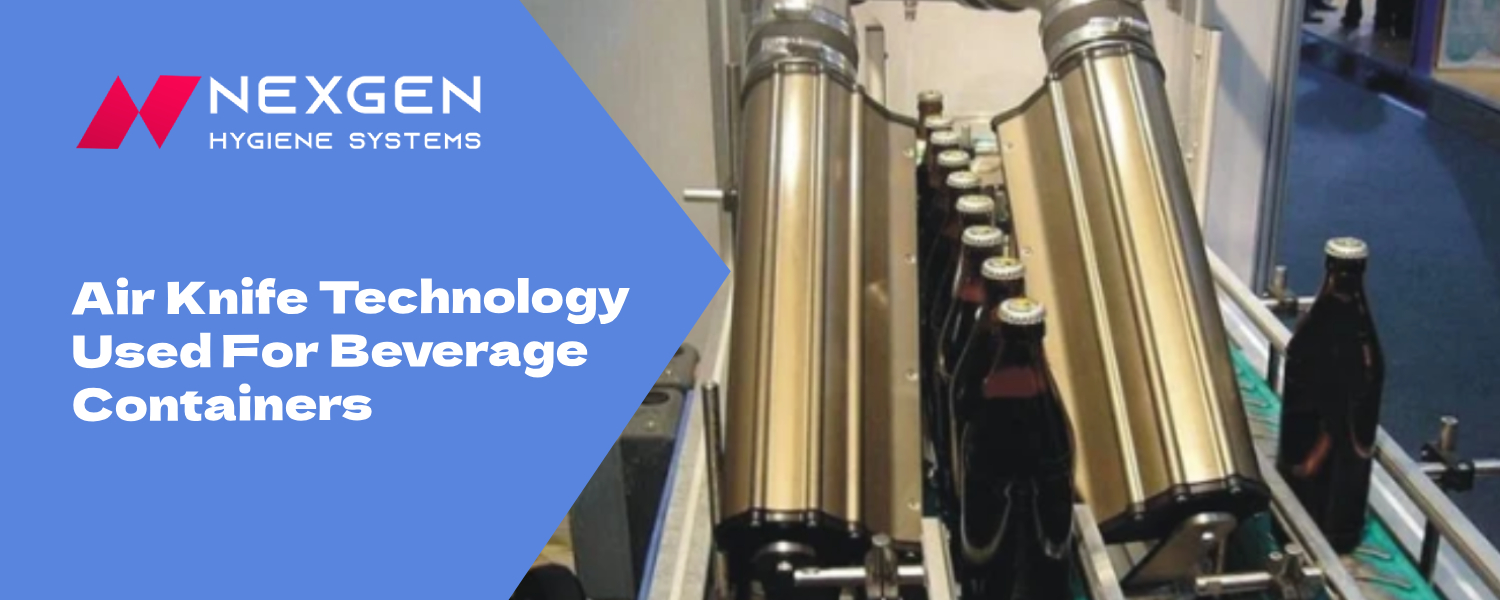

Beverage Containers

In beverage production, air knives are essential for cleaning bottles, cans, and other containers before filling. This ensures that the containers are free from dust, debris, or moisture, making them ready for accurate labeling and safe packaging.

Conclusion

Air knife technology is proving to be an indispensable tool in modern food processing, offering efficiency, safety, and cost benefits that are hard to ignore. As the food industry continues to evolve, so will air knife systems’ applications and capabilities. Whether you’re drying, cleaning, or cooling food products, integrating air knives into your process could be the key to staying ahead in this competitive industry.

At NexGen Machines, we understand the critical role that advanced technology plays in maintaining the highest standards of food safety and efficiency. Our commitment to delivering top-notch solutions means that we’re always exploring the best ways to enhance your food processing capabilities. Whether it’s through cutting-edge air knife systems or other innovative hygiene solutions, we’re here to help you achieve operational excellence and stay ahead in a competitive market.

Stay competitive with NexGen's advanced Air Knife Technology

Get in TouchFAQs

What are the main benefits of using air knife technology in food processing?

Air knife technology increases efficiency, reduces waste, and enhances product safety by providing consistent drying, cleaning, and cooling.

How do air knives contribute to food safety and hygiene?

Air knives help remove debris and contaminants from food products, reducing the risk of contamination and ensuring a cleaner final product.

Can air knife systems be integrated with existing food processing equipment?

Yes, air knife systems can often be retrofitted or integrated with existing equipment, making them a versatile addition to any processing line.

What types of food products can benefit from air knife technology?

A wide range of food products, including vegetables, snacks, baked goods, and meats, can benefit from air knife drying and cleaning systems.

What is the effect of the air knife?

The primary effect of an air knife is to deliver a controlled stream of air that can dry, clean, or cool products quickly and efficiently.

What is the speed of the air knife?

The speed of an air knife can vary, but it typically produces airflows in the range of 20,000 to 40,000 feet per minute.

What are the different types of air knives used in food processing?

The most common types include linear, Coanda, and circular air knives, each suited to different applications within the industry.