Cashew processing is a complex operation that involves several stages from shelling to drying, separating, and peeling the cashew nuts. For large-scale industries involved in cashew kernel production, export, or distribution, the right machinery is crucial to maintaining efficiency, minimizing waste, and producing high-quality kernels for the market. This guide will walk you through the various types of cashew processing machines, focusing on their key roles in ensuring smooth operations within your production facility.

Raw Cashew Sizer

The processing of cashews starts with sorting the raw cashew nuts according to their size. The raw cashew sizer plays a critical role in this stage by categorizing nuts based on their dimensions. Proper sizing ensures that the cashew nuts are treated appropriately during the shelling process, as different sizes require different levels of pressure for cracking. Using a raw cashew sizer not only optimizes the processing time but also reduces the chances of breakage, which can affect the yield of whole kernels.

A well-designed raw cashew sizer is essential for maintaining the integrity of the kernels and enhancing overall productivity in large-scale operations. The machine can handle large volumes of cashew nuts, separating them quickly and efficiently to keep the rest of the processing line running smoothly.

Cashew Peeling Machine

Peeling is one of the most crucial stages in cashew processing. After the cashews have been steamed or boiled to soften their outer shell, they are fed into peeling machines that remove the inner skin without damaging the kernels. Depending on the scale of operation, there are several types of cashew peeling machines available:

Single Head Cashew Peeling Machine

This machine is ideal for smaller batches or operations where production volumes are moderate. With a focus on precision, the single head cashew peeling machine removes the outer layer from the kernels without causing any damage, ensuring a high yield of unbroken kernels.

Compact Double Head Cashew Peeling Machine

The double head peeling machine is a more efficient option for medium to large operations. It can handle a higher volume of cashews per cycle, making it a better fit for businesses looking to scale up their production without compromising quality.

Compact Four Head Cashew Peeling Machine

For large-scale operations, the four head peeling machine offers unmatched productivity. Capable of processing significant quantities of cashews simultaneously, this machine ensures that even the largest production runs are handled with efficiency and care. Its compact design allows it to fit seamlessly into a larger processing line without requiring excessive space.

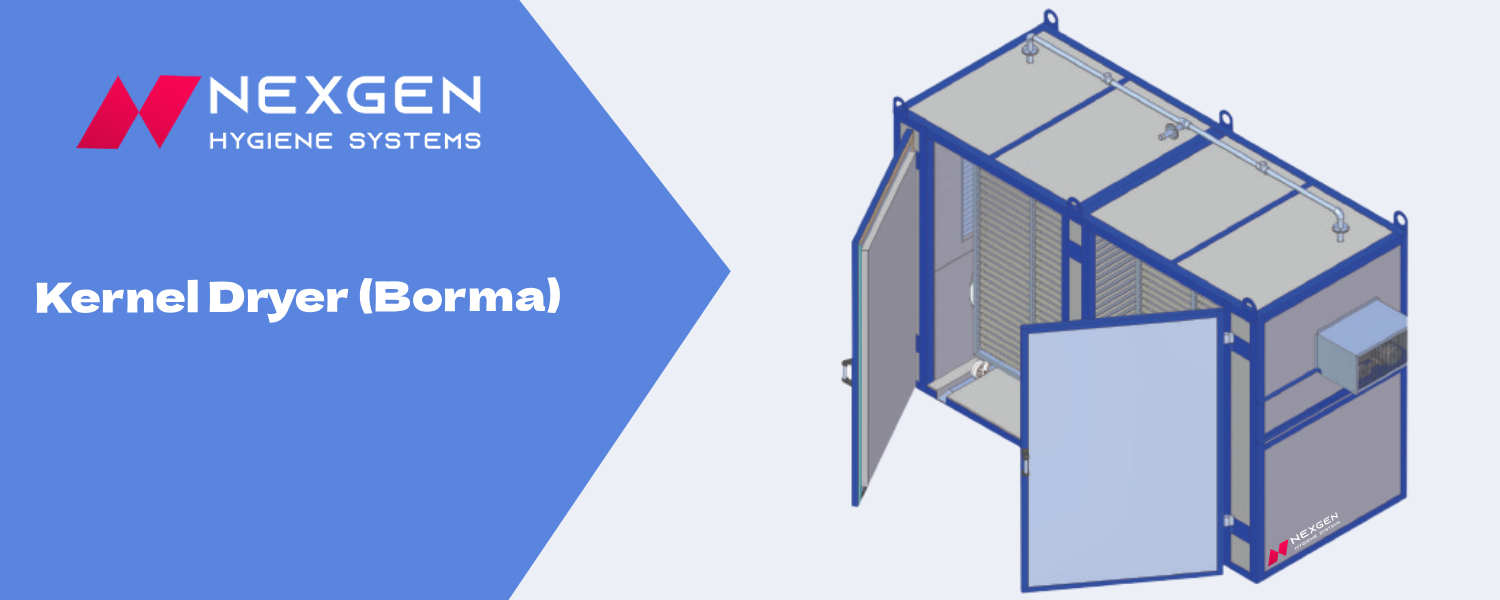

Kernel Dryer (Borma)

After peeling, the moisture content of the cashew kernel needs to be reduced to extend its shelf life and maintain its quality. This is where the kernel dryer, also known as a Borma, comes into play. Drying the kernels is a crucial step in preventing mold growth and ensuring that the cashews can be safely stored and transported.

A kernel dryer is typically used to remove the residual moisture content in the cashews after the initial drying phase post-shelling. This machine allows for consistent drying by maintaining a controlled temperature, which is critical for preserving the texture and flavor of the cashew. In large-scale cashew processing operations, investing in a high-capacity kernel dryer can significantly improve efficiency and product quality.

Cashew Scooping Machine

The cashew scooping machine is another vital piece of equipment in the processing line. This machine is responsible for separating the kernels from the broken cashew shells. After the shelling process, it’s common for pieces of shells to remain mixed with the kernels, and manual sorting can be time-consuming and inefficient.

The cashew scooping machine automates this process, making it faster and more accurate. By using a combination of vibratory and oscillatory motions, the machine effectively separates the shells from the kernels, ensuring that the final product is free from contaminants. For large-scale operations, having a reliable cashew scooping machine is essential for maintaining production speed and consistency.

Oscillator and Vibrator - Kernel, Half Cut, Uncut, Shells Separator

Separating kernels from uncut and half-cut cashews, as well as removing the shells, is a precise process that requires specialized machinery. The oscillator and vibrator unit is designed to ensure that each piece is separated correctly, maximizing yield and reducing waste.

This machine uses oscillation and vibration to gently move the cashew kernels while allowing gravity to sort them according to size and cut. The shell separator then removes any remaining shell fragments from the kernels, ensuring a clean and high-quality final product. This is particularly important in large-scale production, where efficiency and accuracy can directly impact profitability.

The Importance of Choosing the Right Cashew Processing Machines

For any business involved in the large-scale production and export of cashews, investing in the right cashew processing machines is essential for maintaining operational efficiency and producing high-quality kernels. Each machine plays a specific role in the process, from sorting and peeling to drying and separating. By automating these processes, companies can reduce labor costs, increase production speed, and ensure that their products meet industry standards for quality.

When selecting machinery, it’s important to consider factors like throughput capacity, automation level, and ease of maintenance. Working with reliable cashew processing machine manufacturers can help ensure that your investment in equipment is sound and long-lasting.

Stay competitive with NexGen's Cashew Processing Machines

Let’s get started!Conclusion

Cashew processing requires a variety of machines to handle each stage of production efficiently. From the initial sizing of raw nuts to the final peeling and drying, each machine plays a critical role in delivering high-quality cashew kernels for the market. For large-scale operations, having the right equipment can make all the difference in terms of productivity, product quality, and profitability. Whether you’re processing cashews for local distribution or global export, investing in the right machinery is essential to success.

FAQs

Why should large-scale industries use automatic cashew processing machines?

Automatic cashew processing machines streamline the entire production process, reducing manual labor, increasing efficiency, and ensuring consistent product quality.

How does automation benefit cashew processing operations?

Automation reduces manual labor, speeds up the production process, and enhances consistency in quality, making it ideal for high-volume cashew processing.

What is a raw cashew sizer’s capacity in large-scale production?

Raw cashew sizers are designed to handle large volumes, typically sorting thousands of cashews per hour depending on the machine model.

How important is maintenance for cashew processing machines?

Regular maintenance of cashew processing machines is crucial for ensuring longevity and optimal performance. Well-maintained machines reduce downtime, minimize repair costs, and maintain consistent product quality.

What factors should I consider when purchasing a cashew processing machine?

When buying a cashew processing machine, consider factors such as production capacity, automation level, ease of operation, and support from the manufacturer. The machine should be durable, easy to maintain, and capable of handling the volume of nuts you plan to process.