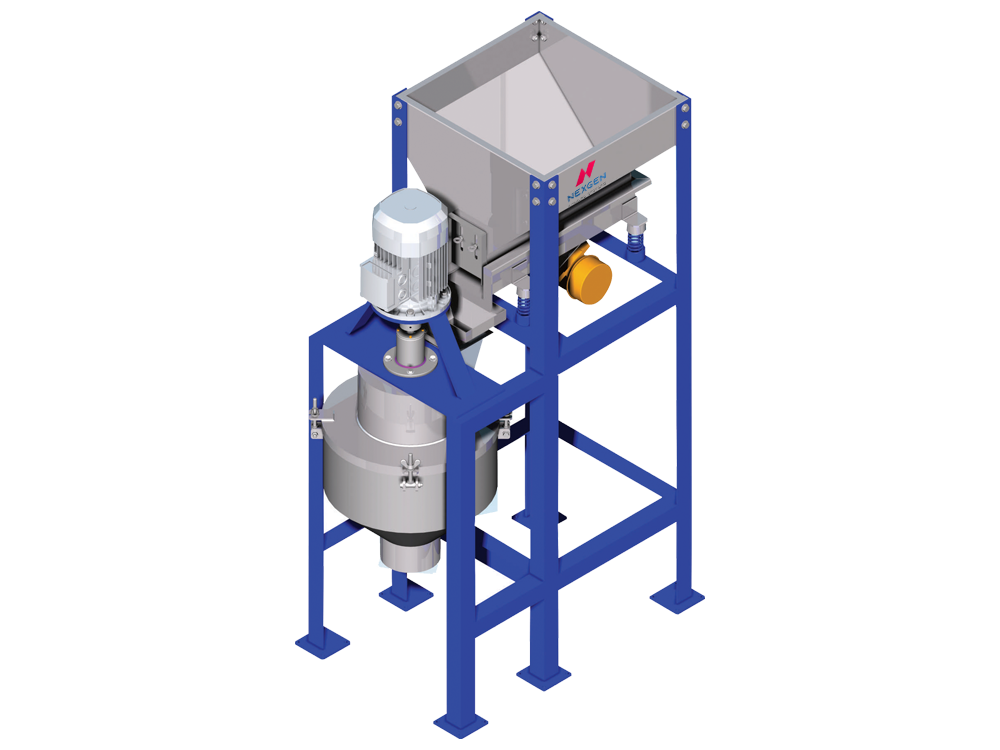

Cashew processing involves several steps from shelling to sorting, aiming to produce high-quality kernels while minimizing manual labor and maximizing efficiency. Nexgen Hygiene Systems offers a range of advanced machinery tailored to streamline every stage of the cashew processing journey.

Cashew Processing Machines

Elevating Quality Standards with Every Kernel

Transform your cashew processing with our advanced machinery, optimizing efficiency and quality at every stage. Tailored for shelling, sorting, and packaging, our solutions meet unique demands, ensuring superior outcomes while maximizing productivity and minimizing manual labor.

OVERVIEW

What is Cashew Processing?

Features of Cashew Processing

Automated Operation

Completely automatic dry-peel operation for efficient and labor-saving processing.

Energy Efficiency

Energy-saving units with compact designs ensure high production efficiency while minimizing operational costs.

User-Friendly Technology

Easy-to-operate systems with automatic in-feed devices and customizable settings for different cashew sizes.

Maintenance and Cleaning

Equipment designed for easy maintenance and cleaning, enhancing overall hygiene and operational efficiency.

Versatility

Machinery capable of handling various sizes and types of cashews, adaptable to different production setups.

Customization

Equipment can be customized according to specific customer requirements, ensuring optimal performance in diverse processing environments.

IMPACT

Importance of Cashew Processing

High Production Efficiency

Advanced machinery leads to increased productivity and reduced manual labor, optimizing overall production output.

Ease of Operation and Maintenance

User-friendly technology ensures easy operation and maintenance, minimizing downtime and enhancing operational efficiency.

Customized Solutions

Tailored equipment and systems meet specific processing needs, providing flexibility and adaptability in various production environments.

Industry Expertise

With years of experience in the industry, Nexgen Hygiene Systems offers innovative solutions backed by industry expertise and customer support.

APPLICATIONS

Industry Applications

Hygiene stations have a wide range of industry applications where cleanliness and safety are paramount. Here are some of the key industries that benefit from hygiene stations:

Cashew Kernels Production

Export and Distribution

Snacks and Namkeen

Why Choose Nexgen Hygiene Systems

Nexgen Hygiene Systems stands out as a trusted partner in providing innovative and reliable hygiene solutions for your business. We offer a comprehensive range of cutting-edge products and services designed to streamline operations, enhance cleanliness, and improve efficiency. With our commitment to quality, customer satisfaction, and industry expertise, we are the go-to choice for businesses seeking to elevate their production journey.

Streamlined Integration

Our solutions seamlessly integrate into your existing cashew processing line, minimizing disruptions and maximizing productivity.

Customer Support

Our dedicated team provides exceptional support to help you achieve your goals and maintain high standards.

Continuous Improvement

At Nexgen Hygiene Systems, we are committed to ongoing research and development, continuously innovating our products.

OUR CLIENTS

Delivering excellence in every partnership

FAQs

Frequently Asked Questions

What types of cashew processing equipment does Nexgen offer?

Nexgen Hygiene Systems offers a wide range of cashew processing equipment, including machinery for shelling, sorting, peeling, and packaging. Our solutions are designed to cater to various stages of the cashew processing journey, ensuring efficiency and quality.

Are Nexgen's cashew processing solutions customizable?

Yes, our cashew processing solutions can be customized to suit your specific production needs and facility requirements. Whether you need equipment tailored for different cashew sizes or specialized machinery for unique processing challenges, we can provide customized solutions to meet your demands.

How can Nexgen's cashew processing solutions help with compliance?

Our cashew processing equipment is designed with hygiene and safety standards in mind, helping businesses comply with industry regulations and ensure product quality. With features such as easy-to-clean surfaces, hygienic design, and precision controls, our solutions facilitate compliance with food safety standards.

What industries can benefit from Nexgen's cashew processing solutions?

Our cashew processing solutions are applicable to a variety of industries, including food processing, snack manufacturing, nut processing, and more. Whether you’re a small-scale cashew processor or a large-scale production facility, our equipment can help optimize your cashew processing operations.

What is the expected lifespan of Nexgen's cashew processing equipment?

Our cashew processing equipment is engineered for durability and long-term performance, providing reliable service for years. With proper maintenance and care, our machinery can withstand the rigors of daily production and deliver consistent results over time.

Do you provide after-sales support and maintenance for your cashew processing equipment?

Yes, we offer comprehensive after-sales support, including maintenance services, spare parts availability, and technical assistance. Our dedicated team is committed to ensuring the smooth operation of your cashew processing equipment and maximizing its lifespan.