Utilize a gentle floatation method with adjustable water flow and air agitation for thorough cleaning of garlic bulbs.

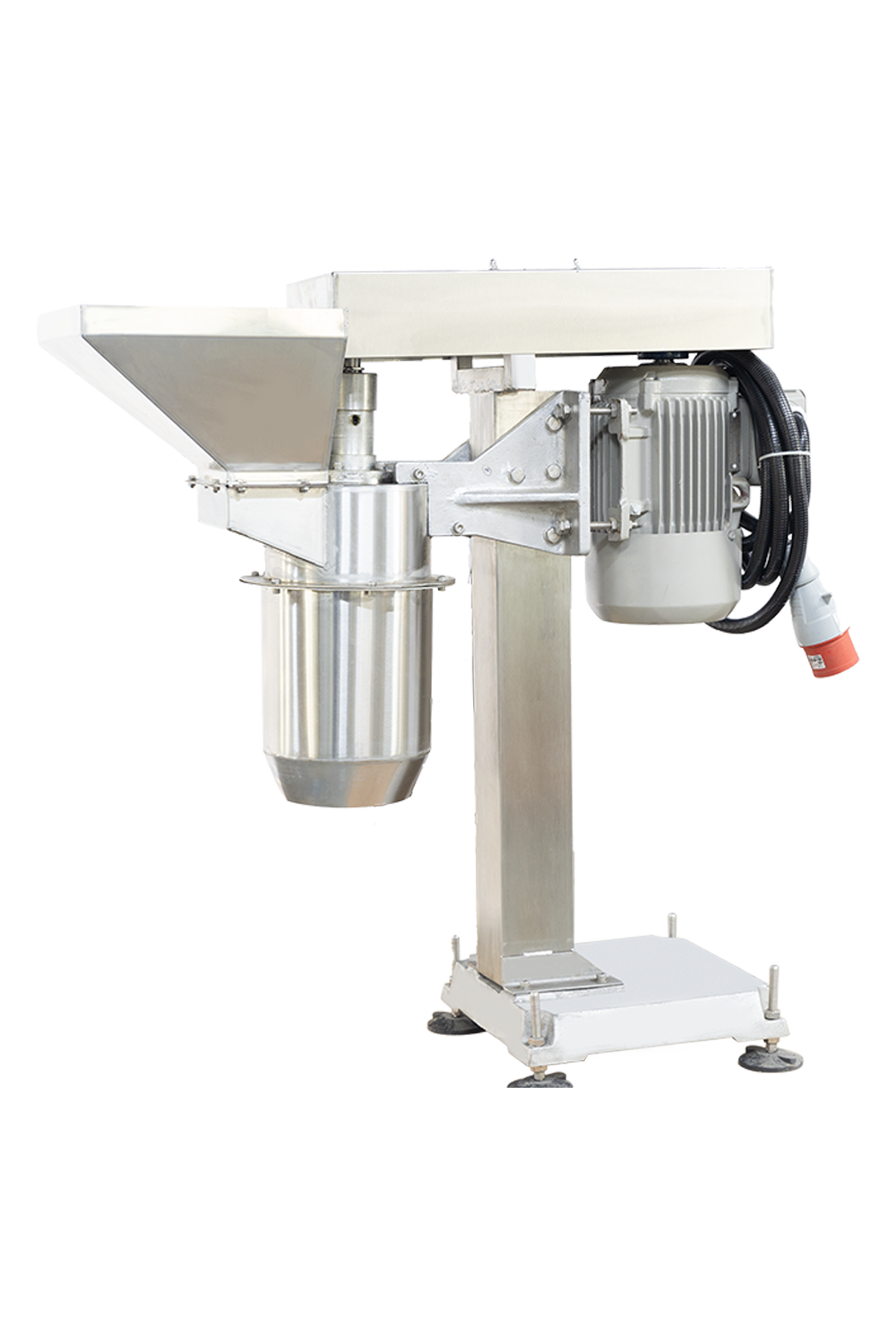

Garlic Float Washer

Ensure cleanliness and hygiene in your garlic processing operations with our Garlic Float Washer. This machine is designed to wash and sanitize garlic bulbs using a gentle floatation method, removing dirt, debris, and other contaminants effectively. Equipped with adjustable water flow and air agitation, it ensures thorough cleaning of garlic bulbs while minimizing product damage. Ideal for food processing plants, agricultural operations, and commercial kitchens, this washer helps maintain food safety standards and ensures high-quality garlic products.

Key Features

1

Thorough Cleaning

2

High Capacity

Wash a large quantity of garlic bulbs per hour to meet production demands.

3

Versatile Usage

Suitable for washing various sizes and varieties of garlic bulbs for various culinary applications.

4

Durable Construction

Built to withstand heavy use and harsh washing environments.

5

Easy Maintenance

Simple upkeep and cleaning for hassle-free operation and maintenance.

Benefits of Garlic Float Washer

Improved Hygiene

Ensure cleanliness and sanitation of garlic bulbs for safe consumption and processing.

Labor Savings

Reduce manual labor and save time with efficient garlic washing capabilities.

Versatility

Adapt to different garlic varieties and processing requirements with customizable washing configurations.

Cost Savings

Minimize waste and improve product shelf life with thorough cleaning and sanitization.

Durability

Invest in a reliable and durable garlic float washer that delivers consistent performance over time.

Technical Specifications

-

Garlic flotation washer with pickup conveyor.

-

Capacity @ 1500-2000 Kg per hour.

-

Suitable for washing the peeled garlic/garlic cloves & separating Floating Particles as much as possible.

-

The product is dumped into the washer where an air blower attached to the unit will agitate it and subsequently wash it with a strong water spray

-

The product will be subjected to four stages of washing

-

Soaking into the water.

-

Agitation in the water to remove the dirt adhering to the surface of the Garlic by air agitation.

-

Subjecting to strong water spray

-

For washing the Garlic and also assisting in pushing forward the Garlic into the washing conveyor.

-

The unit is made of SS304 and comes with a complete with a drive mechanism.

-

A Molded belt takes off the conveyor with specially designed slats for conveying the Garlicand draining the water while conveying is included in the washer.

-

Freshwater sprays will be provided on the pick-up conveyor to rinse the Garlic with fresh water.

-

Power supply Needed : 3 Phase.

-

Provision to remove floating impurities will be incorporated into the machine.