Hygiene stations are cleaning, washing, and sanitizing equipment that helps keep the food processing unit clean and contamination-free.

Today, thanks to the internet and social media, consumer awareness regarding food safety standards is at an all. On top of that, FSSAI and similar agencies have become hyperactive, leaving no room for negligence by food processing and packaging plants.

Hygiene stations (equipment and systems) have come into the picture as a solution. They play a pivotal role in ensuring the safety, quality, and compliance of food production processes.

Imagine a facility where an employee unknowingly carries contaminants on their hands or footwear. In such a case, a well-designed hygiene station can neutralize these threats before they compromise the food supply.

Every industry’s hygiene needs and contamination challenges are different. That’s why these stations, or consolidated hygiene systems, are customized to meet the unique needs of industries like food processing, pharmaceuticals, and healthcare.

For instance, in food processing, hygiene stations focus on stringent measures to eliminate cross-contamination risks and ensure compliance with food safety standards like Food Safety and Standards Authority of India, or FSSAI.

This blog delves into the significance of hygiene stations, their components, types, applications, and benefits, particularly in the food processing sector.

What Is a Hygiene Station?

A hygiene station is a specialized setup that maintains and enforces sanitation standards in areas where cleanliness is vital. It serves as a gatekeeper to ensure that people accessing critical production areas have thoroughly cleaned and sanitized limps and they follow hygiene protocols.

These stations use tools and technology to ensure comprehensive cleaning, disinfection, and monitoring. Employees, for example, can clean their hands and boots at the same time without having to walk between separate units. This makes achieving hygiene and cleanliness much faster, particularly effective when shifts change.

Understanding the Criticality of Hygiene in Food Processing

The food processing industry operates within a delicate ecosystem where even the slightest lapse in hygiene can have far-reaching consequences.

From the moment raw materials enter the facility to the final packaging and distribution of finished products, maintaining a pristine environment is paramount.

The presence of harmful microorganisms such as bacteria, viruses, and fungi can lead to:

Foodborne Illnesses

Contaminated food can cause a range of illnesses in consumers, ranging from minor gastrointestinal discomfort to serious, life-threatening conditions.

Product Recalls

Contaminated products often cause costly and disruptive product recalls, which harm brand reputation and undermine consumer trust.

Regulatory Non-Compliance

Strict food safety regulations, such as those enforced by the Food Safety and Standards Authority of India (FSSAI) in India and equivalent agencies worldwide, demand meticulous adherence to hygiene and cleanliness protocols.

Non-compliance can result in hefty fines, legal challenges, and potentially the temporary or permanent closure of facilities.

Operational Disruptions

Contamination incidents can disrupt production schedules, resulting in lower productivity, higher expenses, and missed deadlines.

Why Are Hygiene Stations Essential in Food Processing?

Hygiene stations, as a food processing equipment, serve as a critical first line of defense in safeguarding food safety and maintaining operational efficiency.

By strategically integrating various components and technologies, these stations effectively address key hygiene concerns:

Ensuring Food Safety

The primary purpose of the food processing sector is to provide safe, consumable products. Hygiene stations serve as the first line of defense against contamination, ensuring that staff and visitors meet sanitation standards before accessing industrial areas.

Preventing Cross-Contamination

Cross-contamination has serious implications, including product recalls, legal challenges, and tarnished reputations. Hygiene stations reduce these dangers by limiting the entrance of contaminants through staff and food processing equipment.

Boosting Consumer Confidence

Trust is like a crumpled paper; once damaged it can never be the same. A visible commitment to hygiene reassures customers about the quality and safety of the products, building trust and loyalty.

Enhancing Operational Efficiency

Proper hygiene stations prevent contamination-related downtime, resulting in smoother operations and higher productivity.

Regulatory Compliance

Food processing units in India are required to implement the Food Safety Management System (FSMS), Good Hygiene Practices (GHP), and Good Manufacturing Practices (GMP), as defined by the FSSAI, effectively. Failure to comply with these regulations could lead to severe consequences, such as hefty fines, suspension of facility operations, or costly product recalls.

Businesses can achieve these demanding criteria with hygiene stations. Combining these stations with monitoring equipment, they can keep detailed records of compliance to use as proof during audits.

Types of Hygiene Stations

Hygiene stations come in a variety of configurations to suit the specific needs and operational requirements of different food processing facilities:

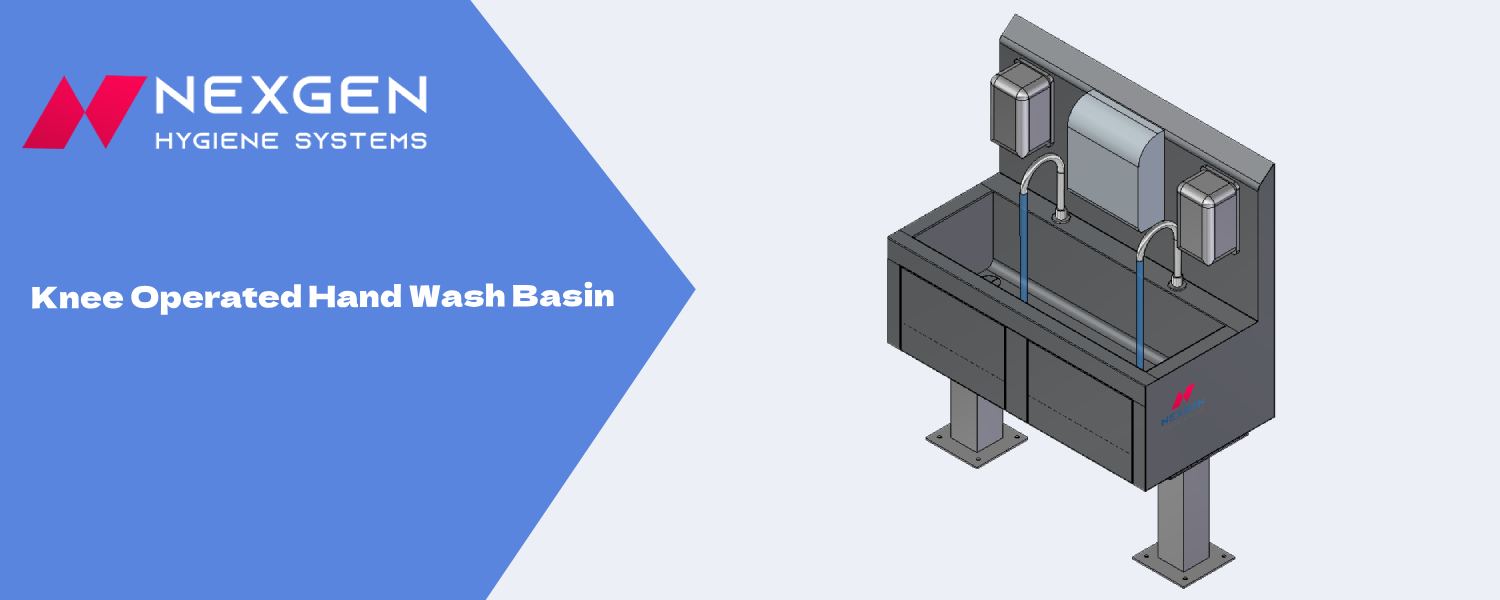

1. Hand washing Stations

Proper handwashing is essential for personal hygiene. Hygiene stations frequently contain cutting-edge technologies such as automatic soap dispensers and touchless faucets, allowing staff to completely wash their hands without the risk of cross-contamination.

Temperature-controlled water systems further enhance the handwashing process by providing the optimal temperature for removing dirt and germs.

Hand washing stations often include sinks, touchless faucets, and soap dispensers to ensure thorough cleaning.

2. Sanitizing Units

Sanitizing units eliminate microbes that remain after washing hands with soap. These machines are frequently integrated into handwashing systems and dispense alcohol-based or non-alcohol sanitizers to give an extra layer of safety.

Touchless technology in modern hand disinfection units reduces cross-contamination dangers and its compact shape allows for easy placement near hygiene stations or access points.

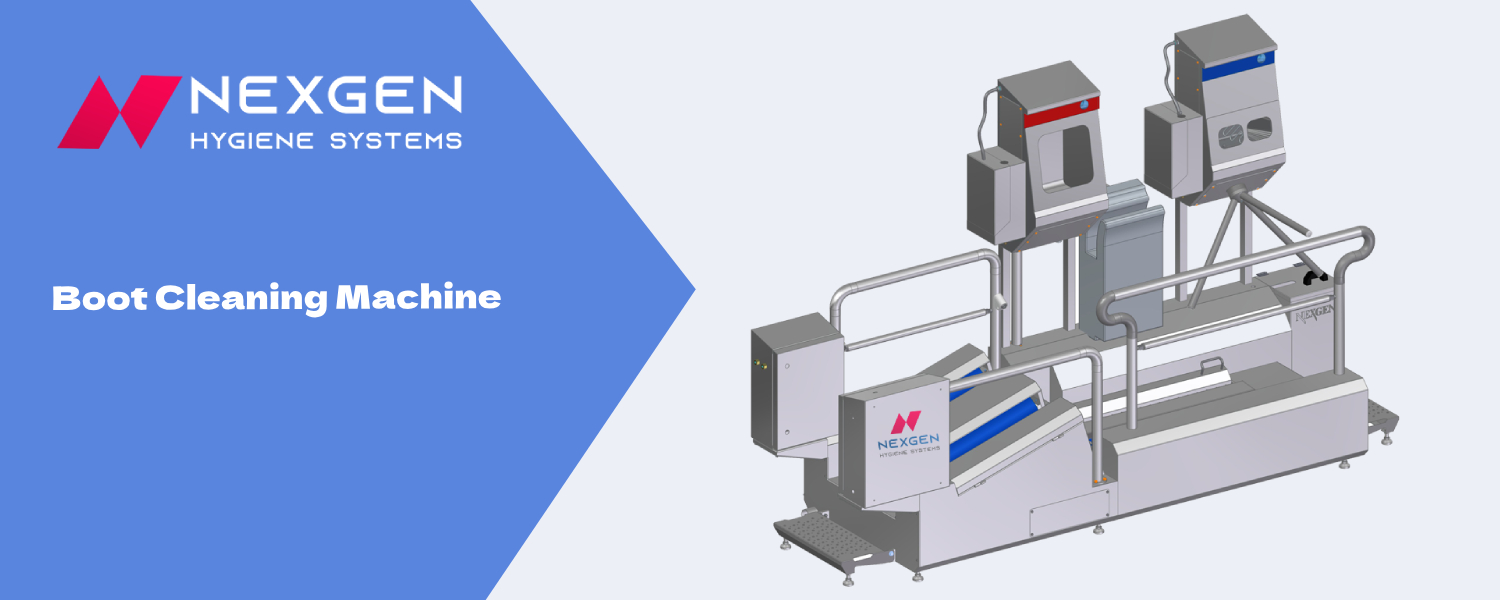

3. Boot Cleaning Machines

Boot cleaning machines are essential for ensuring cleanliness in industries with stringent hygiene standards, such as food processing, healthcare, and manufacturing. These machines use revolving brushes, water jets, and sanitizing solutions to thoroughly clean footwear, removing dirt, debris, and dangerous substances.

Advanced models, like the Gumboot Cleaning Machine, also have automated drying and sanitization sprays for thorough cleaning.

4. Turnstiles and Access Control

Turnstiles combined with hygiene regulations offer a novel approach to access control in restricted or sensitive locations. These systems, which are equipped with sensors and automatic mechanisms, require persons to complete specified hygienic actions, such as handwashing or sanitizing, before allowing them admission.

A turnstile unit for access control in critical zones guarantees that only individuals who adhere to hygienic requirements. Integrate it with a monitoring system, advanced stations can ensure 100% compliance with hygiene regulations and, more importantly, identify potential areas for improvement.

5. Monitoring and Reporting Systems

Systems for tracking and reporting provide up-to-date information on workplace hygiene compliance. These systems track handwashing, sanitization, and other hygiene practices using sophisticated sensors and software, producing management-ready data.

By identifying compliance gaps, the data gathered by these systems permits more focused interventions and increases overall compliance. Some advanced setups also integrate with employee management software, ensuring seamless tracking and auditing.

6. Custom Hygiene Solutions

Food processing and hygiene equipment providers also offer customized hygiene stations to meet the specific needs of the food business.

For instance, NexGen, a food processing equipment manufacturer, integrated automated handwashing machines, boot scrubbing systems, and compliance monitoring tools into a specially designed hygiene station for a dairy processing facility. This approach enhanced operational efficiency and significantly improved the dairy company’s sanitary standards.

These examples illustrate how Original Equipment Manufacturers (OEMs), like NexGen, leverage their expertise to provide solutions that cater to diverse operational challenges and regulatory requirements.

Where Should Hygiene Stations Be Installed?

Hygiene stations are critical in multiple areas within food processing facilities:

Employee Entry Points

Hygiene stations at employee access points act as a first line of defense, ensuring that all staff entering production areas follow hygiene protocols.

Production Zones

Hygiene stations are essential for preserving cleanliness and avoiding contamination in production spaces where food items are handled and processed.

Packaging Areas

Packaging areas require perfect hygiene controls to safeguard the safety and quality of finished products. Hygiene stations ensure that personnel handling packaging materials carry no contamination.

Visitor Areas

Hygiene stations at visitor areas are important because the outsiders may, unintentionally, introduce contaminants into the plant.

Storage Facilities

Due to the extended presence of materials and fluctuating temperature and humidity, which can promote microbial development, storage rooms are especially susceptible to contamination. Hygiene stations protect raw materials and completed commodities by preventing contamination in storage areas.

Conclusion

In the food processing business, hygiene stations are essential for upholding integrity of food products, their quality, and compliance standards. They also help to mitigate cross-contamination.

With creative and dependable hygiene solutions catered to the particular requirements of food processing facilities, businesses such as NexGen Machines set the standard.

Manufacturers of food processing equipment can preserve operations, secure customer health, and keep a competitive edge by making the appropriate hygiene station investments. Learn how NexGen’s state-of-the-art hygiene stations may improve the hygienic standards of your establishment.

FAQs

Why Is Personal Hygiene Important in the Industry?

In the food processing business, maintaining personal cleanliness is crucial for preventing the spread of harmful contaminants and germs. Employees’ hands, clothing, and footwear can harbor pathogens, which, if transferred to food products, may lead to contamination, foodborne illnesses, and costly recalls. Hygiene stations ensure that personnel entering critical areas adhere to stringent sanitation standards, safeguarding product safety and consumer health.

What Food Products Are at High Risk of Contamination?

Food products at high risk of contamination include:

- Raw Meats and Poultry: Susceptible to pathogens like Salmonella, E. coli, and Campylobacter.

- Seafood: Risky due to potential contamination from Vibrio bacteria and parasites.

- Dairy Products: Prone to spoilage and contamination by Listeria and other bacteria.

- Ready-to-Eat Foods: Vulnerable to cross-contamination during processing and packaging.

- Fruits and Vegetables: Especially those consumed raw, as they can carry bacteria, pesticides, or viruses.

Implementing strict hygiene protocols and proper storage conditions minimizes the risks associated with these high-risk foods.

What Are the Five Principles of Food Hygiene?

The five principles of food hygiene are foundational to maintaining safe food production practices. They are:

- Prevent Cross-Contamination: Keep raw and cooked foods separate to avoid the transfer of harmful pathogens.

- Cook Food Thoroughly: Ensure that foods are cooked to safe internal temperatures to kill bacteria and viruses.

- Store Food Properly: Use appropriate refrigeration and storage techniques to maintain food safety and quality.

- Practice Personal Hygiene: Encourage employees to wash hands, sanitize, and wear clean uniforms before handling food.Maintain Clean

- Equipment and Facilities: Regularly clean and sanitize all surfaces, utensils, and machinery used in food preparation.

What Are the 5 C's of Food Safety?

The researchers at World Health Organization (WHO) and Pan America Health Organization (PAHO), collectively, classified the five basic themes of food safety, known as the 5C’s of food safety. They are:

- Cooking: Cook food to appropriate temperatures to kill harmful organisms.

- Cleaning: Maintain a clean environment and practice regular handwashing.

- Cross-Contamination Prevention: Use separate equipment and workspaces for raw and cooked items.

- Chilling: Store perishable items at safe refrigeration temperatures, which is a temperature below 5°C or 41°F.

- Checking: Always check the use-by dates of food items and ensure that anything past its expiration date is not used or consumed by anyone.

How to Keep Food Products Contamination Free?

The food manufacturing, processing, packaging, and retail companies must follow a multi-dimensional approach to ensure that the food product is contamination free. The approach includes installing hygiene stations, doing hazard analysis, maintaining optimal temperature and humidity conditions through the supply chain, and proper employee training on food safety and hygiene practices.